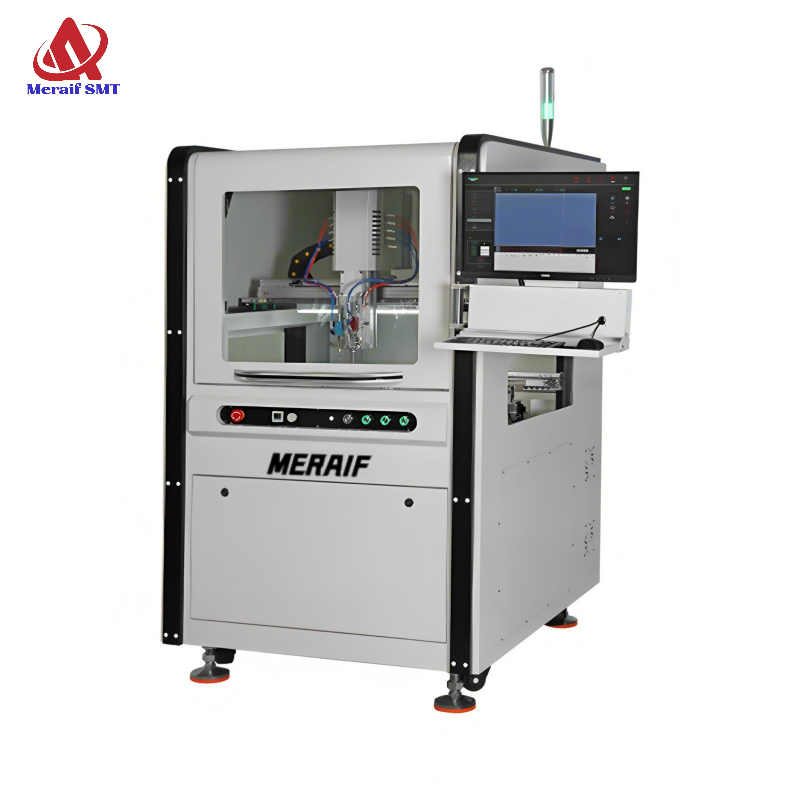

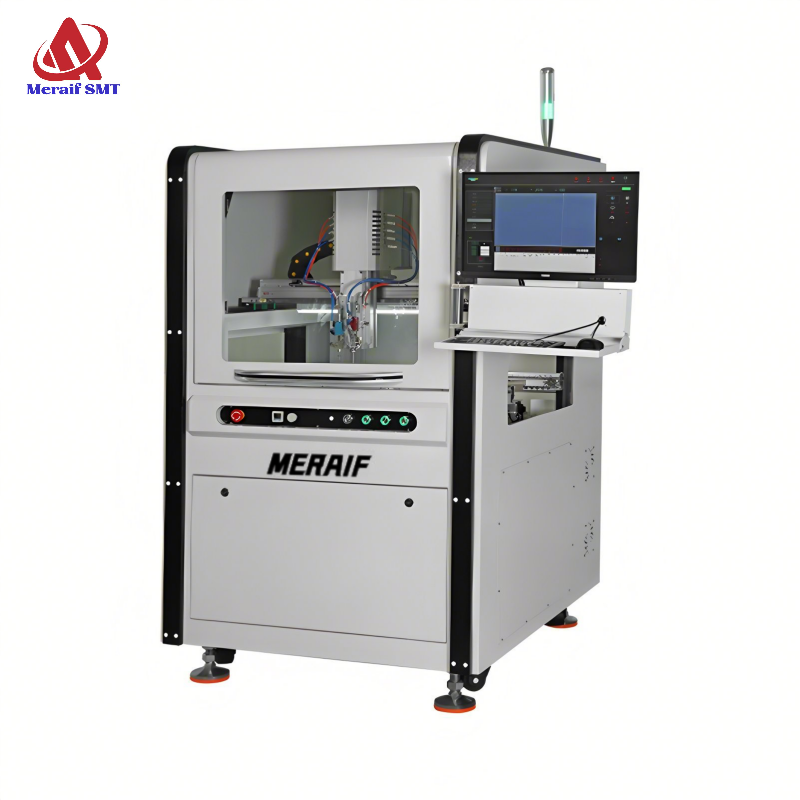

MERAIF MF-P30 PCB Inspection Conveyor PCB Conveyor PCB Coating Machine Conveyor PCB Conveyor System For PCB Coating Machine Line

Whatsapp:+8613728632793, skype:Joaquin Xie,wechat:Joaquin15

Whatsapp:+8613424013606,skype:sensenhenhao,wechat:JoyLY0322

WE are smt support provider for smt machine parts and equipment .such as feeder,nozzle , feeder storage cart smt reel rack , smt grease , solder paste mixer, smd counter, KIC thermal profiler,smt tape and so on .

Also can support some original parts of machine repair.

Successful Experience:

1. We Have Been Helping Customers To Build a Lot of New Factories Around the World.Meraif's Customer In 35 Countries Around the World

2. Training More Than 500 Experts and Technician for Customers.

3. Became the Most Reliable Chinese Partner for You.

For SMT Factory Setup, We Can Do for You:

1. We Provide Full SMT Solution for You

2. We Provide Core Technology With Our Equipments

3. We Provide The Most Professional Tech Service

4. We Have Wealthy Experience on SMT Factory Setup

MERAIF PCB Inspection Conveyor Technical Parameters :

MERAIF PCB Inspection Conveyor Details:

Specifications

Parameter

Model

MF-P30

Overall dimensions L*W*H

L800mm*W960mm*H1260

Power supply

AC220V 50/60HZ

Total power

0.2KW

Equipment weight

90KG

Conveyor rail width

50-450mm adjustable

PCB board component height

Maximum 100mm up and down

Lighting part

Built-in lighting source

Detection part

Built-in detection light source

Conveyor to ground height

920±20mm

Conveyor direction

L-R/R-L

PCB The inspection docking station is mainly used in the electronics manufacturing industry, especially in the SMT (surface mount technology) production line. It is used to transfer PCB boards between the placement machine and the reflow oven or wave soldering equipment to ensure the continuity and efficiency of the production process. In addition, the inspection docking station is also equipped with a solder paste detection device to monitor the printing quality in real time, thereby improving production efficiency and reducing the defective rate.

Features:

1. The conveying mechanism uses a special aluminum profile conveying track and a special stainless steel chain. A special manual (crank) mechanism is used to adjust the track width.

2. The conveying mechanism uses an adjustable speed motor. The frame structure is made of 50 * 50mm square tube, the bottom is equipped with a height adjustment cup, the outside is made of 1.5mm plate, and the surface is electrostatically sprayed with computer white.

3. UV detection uses a special LED ultraviolet detection lamp as the detection light source.

4. The control system uses button control + sensor, the line layout is reasonable, the wiring is neat, the line is installed in the wire trough, and the overall layout line needs to be safe and beautiful.

5. The conveying is the upper conveying, and the conveying of the plate is smooth, without abnormal sound, and the plate is not stuck or hit.

6. The UV detection is manually controlled to release and pause the conveying system conveying fixture and can check the surface coating effect of the product online.

7. Check the size of the viewing port for sprayed products. The size should be designed to ensure that the product delivery fixture can be easily taken out from the viewing port.

MERAIF Pcb Coating Machine Picture Show:

EXHIBITION:

SMT LINE: